Have you ever sipped sake and wondered how fermented rice could produce such a smooth, unique drink? As sake experts, we can tell you. Let’s explore the sake-making process.

What Is in Sake?

Traditional sake recipes are fairly simple, consisting of just a few ingredients. Typical sake ingredients include:

- Water: Did you know sake contains mostly water? At Takara Sake USA, we take great care in sourcing the highest-quality water from the Sierra Nevada Mountains for the best results.

- Rice: Sake rice is different from ordinary cooking rice in that it has much larger grains with a defined yet soft core.

- Koji: This culinary fungus is used in various Japanese foods and beverages, including sake, soy sauce, vinegar, miso paste, and shochu. It’s essential for the fermentation process.

- Yeast: Just like with beer and wine, cultured yeast is a vital ingredient for brewing sake.

Some brewmasters will also add brewers alcohol to further refine the taste of their sake, though it’s not strictly necessary.

The Step-by-Step Sake Brewing Process

Want to know how our brewmasters make premium sake? Here’s a quick overview of how we do it.

1. Polishing

Once we’ve sourced our rice, we polish it in a specialized milling machine. The machine spins the rice grains through a series of disks, gently stripping away the outer bran until the grains reach the desired weight. This process can take as long as 10 hours, depending on your intended result.

The polishing ratio — the percentage of grain remaining after the polishing stage — determines the type of sake we’re making.

Generally, higher polishing ratios will result in a full-bodied, acidic sake, such as our Sho Chiku Bai Classic Junmai. Lower polishing ratios create sake that is more delicate in flavor and aroma, like our Sho Chiku Bai Junmai Daiginjo.

2. Washing

After polishing, we gently rinse the rice to remove any impurities, such as remaining pieces of bran, from the grains. The rice washing stage is essential because it helps protect the sake’s final flavor — as a result, it’s one of the most carefully controlled steps in the entire brewing process.

3. Soaking

We then carefully soak the washed rice to rehydrate the kernels in preparation for steaming. The more polished the rice is, the quicker it will absorb water and the less soaking it will need. This step can take anywhere from a few minutes for a 50% polished Junmai Daiginjo to a full night for an 70% Junmai.

4. Steaming and Cooling

Next, we gently steam the rice until it’s firm on the outside and soft on the inside. The trick here is to keep the rice from coming into direct contact with the hot water — if the two meet, the rice will become too soft for fermentation. This step is another vital process because it makes the rice core easier for the koji to break down later.

After steaming, we remove about one-fifth of the rice and cool it separately to prepare it for making koji. The rest — known as kakemai — will be our base for our fermentation mash.

5. Koji Making

The koji-making process is one of the most critical steps in making sake. Without it, the rice literally can’t ferment. Adding koji to our steamed rice helps convert the starch into sugar, which allows the yeast enzymes to create alcohol during the rice fermentation process.

We spread the steamed rice out on a table known as a toko, then sprinkle it with koji spores and mix it all together. Then, we clump it all together into a ball and tightly cover it with a cloth to ensure a consistent environment.

Over the next two days, the koji enzymes will work their magic. We’ll know the rice is ready when we see haze, or white spots, on the surface of the grains.

6. Shubo Making

Before we can get to the main parts of the sake-making process, we have to prepare our shubo — a fermentation starter containing koji, steamed rice, yeast and extra water. We ferment this mixture in a small tank for up to two weeks, when our sake ingredients are finally ready to start brewing.

7. Moromi Making

The next step is to make the fermentation mash, or moromi. First, we put koji, steamed rice, shubo and some water in a large tank. Over the course of several days, we gradually add more of each ingredient to allow everything to fully combine. This incremental process, known as sandan jikomi, prevents unwanted bacteria growth and enables the sake to develop a more complex flavor.

8. Fermentation

Once our moromi is ready, we seal the tank and allow it to rest for two to four weeks.

Although people often refer to sake as “rice wine,” it’s actually very different from wine. Because grapes already contain sugar, the fermentation process only consists of one step — adding yeast and allowing it to convert the sugar into alcohol over time.

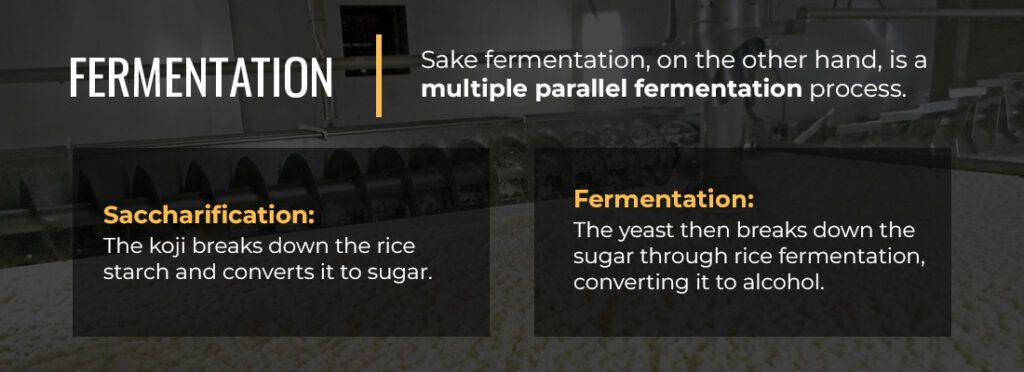

Sake fermentation, on the other hand, is a multiple parallel fermentation process where two processes take place simultaneously:

- Saccharification: The koji breaks down the rice starch and converts it to sugar.

- Fermentation: The yeast then breaks down the sugar through rice fermentation, converting it to alcohol.

This double fermentation process results in a naturally high alcohol by volume (ABV) percentage of about 20% — much higher than your standard beer or wine.

9. Pressing

Several weeks later, we transfer the moromi from the fermentation tank to a Yabuta — a hydraulic press that separates the liquid sake from the solid rice. Although it’s not the traditional pressing method, using a Yabuta is the safest and most effective means of pressing sake out there.

10. Filtering

After removing the solids from the sake through pressing, we pass it through specialized charcoal filters to remove any lingering solids. In addition to catching solid particles on its surface, the charcoal also kills bacteria that can affect the sake’s final taste and aroma.

Notably, nigori sake does not go through filtration. Skipping this step means it retains the solid rice particles, which lend it a cloudy appearance and silky, sweet flavor.

11. Pasteurizing

Immediately after filtration, the sake goes through the first round of a two-part pasteurization process. Sake makers heat the liquid between 140 to 150 degrees Fahrenheit, which ends the fermentation process and kills bacteria that could affect the sake’s quality.

12. Aging and Bottling

Brewmasters age most of their sake for up to six months to allow the flavors to settle into a smooth, delicious product. After the aging period, the sake is ready for us to bottle up and ship to our distributors. And then, it’s finally ready for you to drink.

Enjoy Premium Sake From Takara Sake

Now that you know how sake is made, you might be thinking of opening a bottle yourself. At Takara Sake USA, we pride ourselves on producing top-quality sake using new and traditional methods!

Shop our online store to get our sake delivered straight to your door, or explore our blog to learn more about this iconic drink.